Pump Center

Contact Us

Service Hotline

Address: Room 1499, Building 7, Jiang'an Jincheng Community, Yinpen South Road, Yuelu District, Changsha

Dg Type Industrial Boiler Feed Pump

Key words:

category:

Pump Description

Summary

DG type pump is a single suction, multi-stage and segmental boiler feed pump, which is mainly used for medium, low pressure and sub high pressure boiler feed water, and can also be used to transport high-temperature water or corrosive liquid with high temperature and pressure. The temperature range of the conveyed liquid is - 20~150 ℃ (.

Flow range

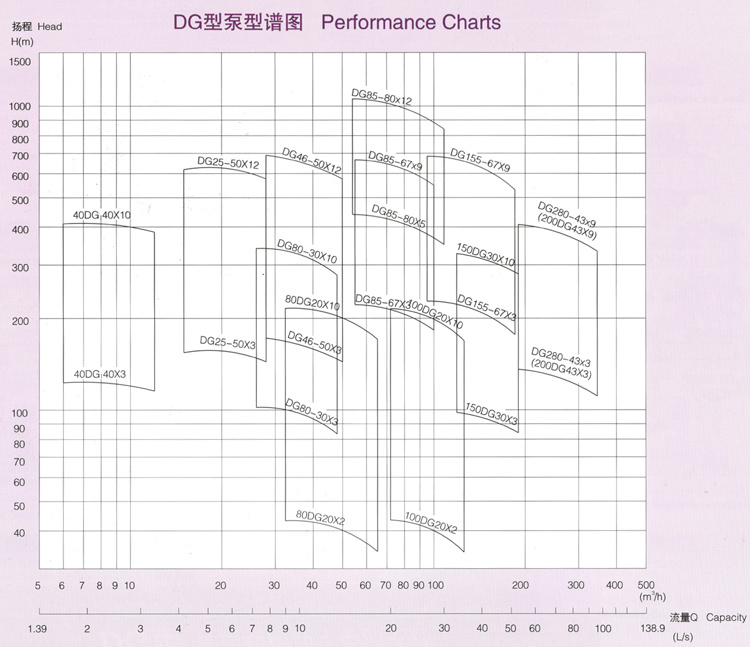

Flow Q: 6 ~ 346 m3/h, lift H: 102 ~ 1056m

Model description

Example DG25-50 × five

DG - multi-stage segmental boiler feed pump

25 - flow of 25m3/h

50 - Single stage lift is 50m

5 - The number of stages is 5

Structural type:

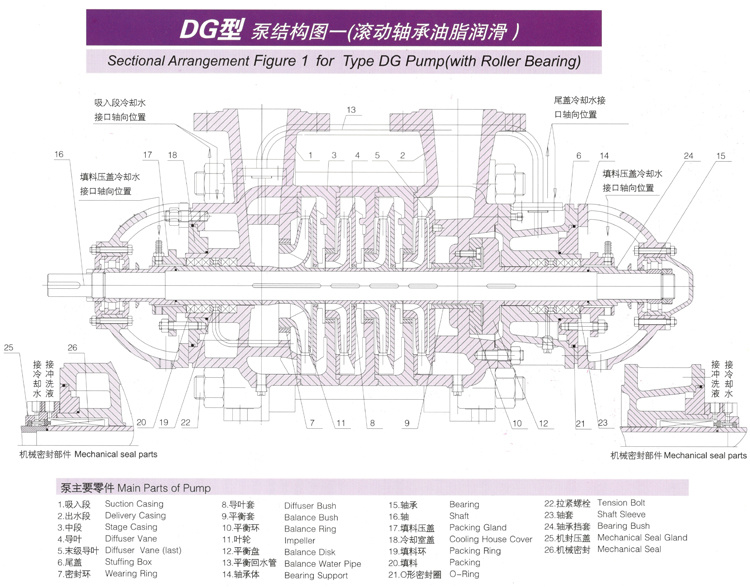

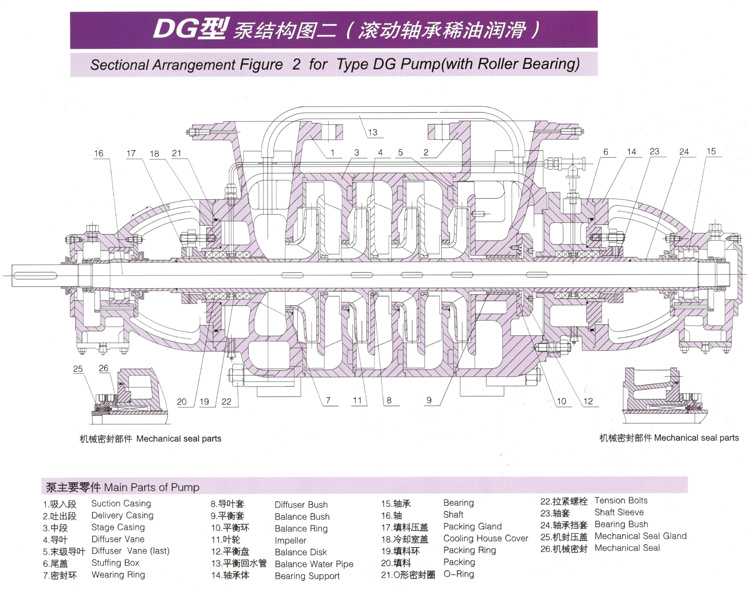

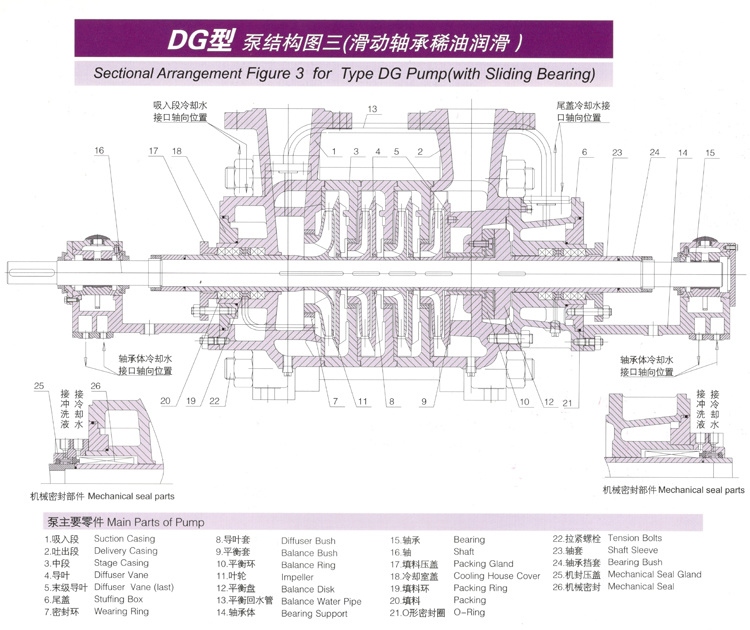

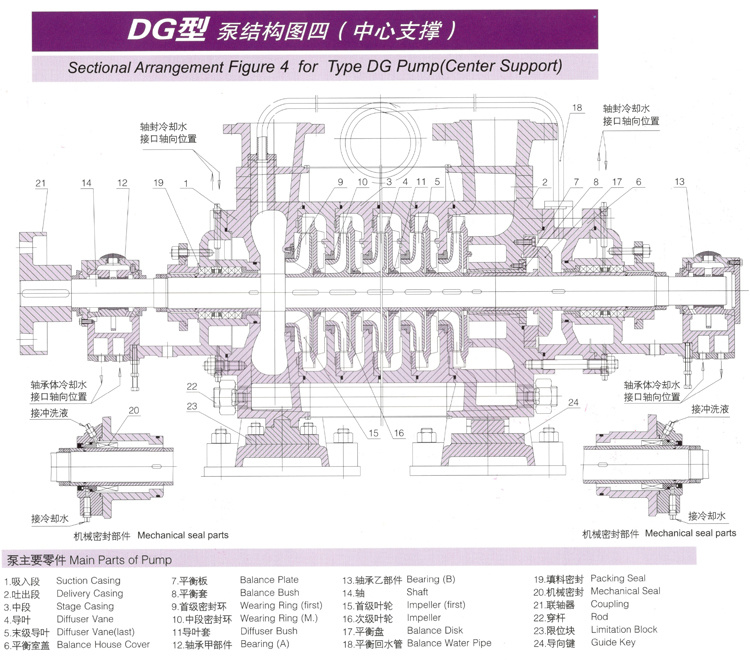

The pump housing is mainly composed of bearing body, suction section, middle section, discharge section and guide vane, which are connected into a whole with pull rod bolts.

The rotor is mainly composed of shaft, impeller, shaft sleeve, balance plate and other parts installed on the shaft. The parts on the shaft are fastened with flat keys and shaft sleeve nuts to integrate with the shaft. The whole rotor is supported on the pump housing by bearings at both ends, and the number of impellers in the rotor part is determined according to the number of stages of the pump.

This type of pump has four structures, one is rolling bearing, lubricated with grease, such as DG46-50 (structure drawing 1), one is rolling bearing thin oil lubrication, such as DG155-67 modified pump (structure drawing 2), one is sliding bearing thin oil lubrication, such as DG85-67, DG155-67 (structure drawing 3), and one is center support, sliding bearing, thin oil lubrication, such as DG85-80 (structure drawing 4).

All structural bearings do not bear axial force. The axial force of the pump is borne by the balance plate. During the operation of the pump, the rotor part is allowed to swim axially in the pump housing. The bearing is lubricated with 32 # turbine oil (thin oil lubrication), 3 # molybdenum disulfide lithium grease (grease lubrication) or other oils with similar performance to obtain better lubrication performance and withstand higher temperature.

Molybdenum disulfide lubrication seals or O-ring seals are used for the seals between the suction section, middle section and discharge section of the pump. The seals between the rotor part and the fixed part depend on the seal ring, guide vane sleeve, packing, etc. When the wear degree of the seal ring and guide vane sleeve has affected the operation and performance of the pump, they should be replaced in a timely manner.

The stuffing box of the pump is equipped with a water-cooled chamber. Some bearing bodies are equipped with water-cooled chambers. The outer surface is equipped with a radiator, which has good cooling protection. The outer surface of the middle shell is equipped with a protective cover to prevent liquid from splashing out between the shell joint surfaces when pumping high-temperature media.

This type of pump adopts packing seal or mechanical seal. The tightness of packing and mechanical seal must be appropriate.

Direction of rotation:

Seen from the motor end, the pump rotates clockwise.

RELATED PRODUCTS

Online Message