Pump Center

Contact Us

Service Hotline

Address: Room 1499, Building 7, Jiang'an Jincheng Community, Yinpen South Road, Yuelu District, Changsha

Ae/se/seh New Generation Single-stage Single Suction Centrifugal Pump

Key words:

category:

Pump Description

Summary:

AE/SE/SEH is a new generation of single-stage single suction centrifugal pump, which is a new generation product after optimizing the hydraulic model and structure on the IS standard pump. Compared with IS series single-stage single suction pump, AE/SE/SEH new generation end suction pump has the following advantages and characteristics:

1. The hydraulic performance of the pump is better. Under the same flow head parameters, the inlet and outlet diameters of some pumps are less than those of IS series pumps, and the efficiency is much higher than that of IS series pumps.

2. New design and manufacturing standards are adopted. AE/SE/SEH new generation end suction pump is in line with international standards, and the design and manufacturing standards adopted comply with ISO5199, ISO2858, GB/T 5656 and GB/T 5657 standards.

Model description

SEH100—65—315

SEH -- Product structure code

100 - Pump inlet flange DN, mm

65 - Pump outlet flange DN, mm

315 - nominal diameter of impeller, mm

AE end suction centrifugal pump

Conform to ISO5199, ISO2858, GB/T 5656 and GB/T 5657 standards.

Application

Sprinkler irrigation, irrigation, drainage, central heating, water supply system, air conditioning system, condensate system, condensate transportation, swimming pool, fire protection system; It is used for water transmission of hot water, cooling water, fire water, industrial water, etc.

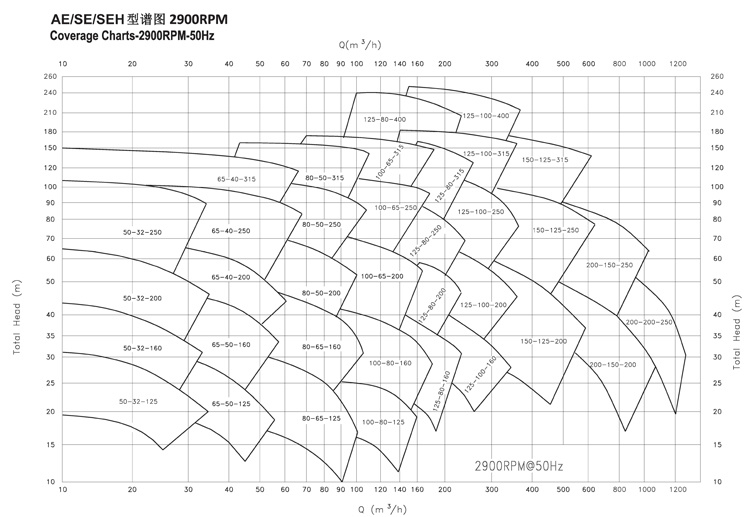

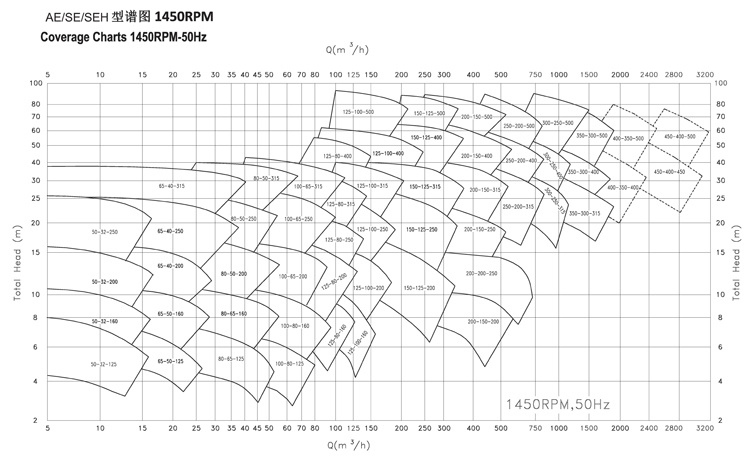

Basic parameters 50Hz operation data

■ Diameter DN32-400

■ Maximum flow 2200m3/h

■ Maximum lift 170 rn

■ Temperature max.+110 ℃

■ Maximum operating pressure: 25bar

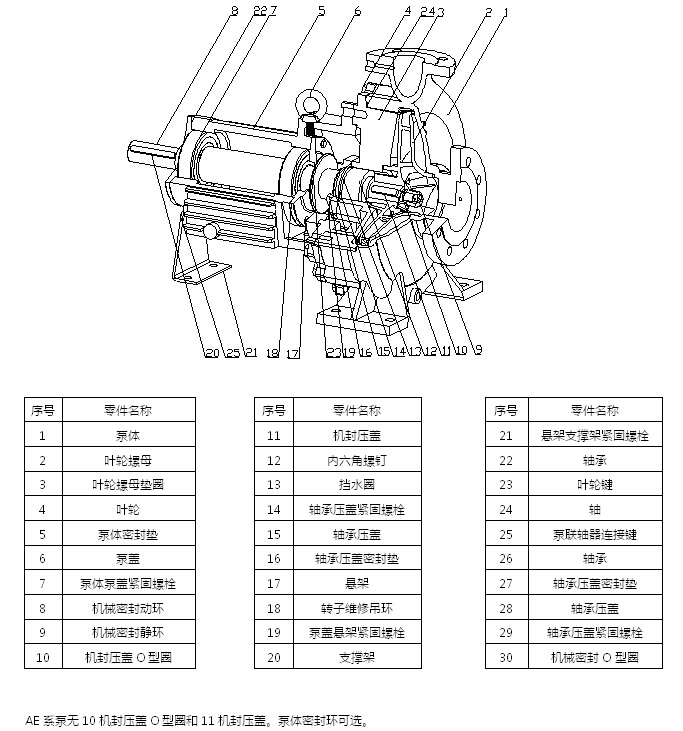

Structural characteristics

■ The pump body with high lift adopts double volute design. The rotor back pumping design is easy to maintain without affecting the pipeline;

■ The main shaft is heavily loaded, and the deviation of the shaft is minimum under the maximum heavy load, so as to ensure the good operation of the running parts on the shaft, more stable pump operation, longer life of the bearing and mechanical seal, and reduce maintenance and repair costs;

■ Excellent hydraulic model of impeller combined with CFD technology to ensure efficient and energy-saving operation;

■ General mechanical seal or cartridge mechanical seal of shaft seal;

■ Modular design of parts, high degree of generalization, and reduction of spare parts inventory;

■ Unique bearing body design and maintenance free closed bearing;

■ Flanges can be manufactured according to GB, ANSI, DIN, JIS and other standards.

texture of material

Grey cast iron, ductile iron, cast steel

SE stainless steel end suction centrifugal pump

Conform to ISO5199, ISO2858, GB/T 5656 and GB/T 5657 standards.

application

■ Liquid transportation in chemical industry

■ Pure water treatment for power plant boiler

■ Pure water and ultrapure water treatment in electronic industry

■ Water treatment for metallurgical industry

■ Sewage treatment

■ High salt water and seawater desalination

■ Bio pharmaceutical industry and food industry

■ Coating industry

■ Hot spring and seawater swimming pool

Basic parameters 50Hz operation data

■ Diameter DNl32-400

■ Maximum flow 2200m3/h

■ Maximum lift 250m

■ Temperature max.+140 ℃

■ Maximum operating pressure CE 42bar,

Structural characteristics

■ The pump body with high lift adopts double volute design. The rotor back pumping design is easy to maintain without affecting the pipeline;

■ Excellent hydraulic model of impeller combined with CFD technology to ensure efficient and energy-saving operation; A variety of impeller structures, including closed impeller, semi open impeller and open impeller. The impeller can be added with auxiliary blades to be suitable for conveying various complex media; If necessary, the inducer can be increased to improve the necessary NPSH;

■ The main shaft is heavily loaded, and the deviation of the shaft is minimum under the maximum heavy load, so as to ensure the good operation of the components on the shaft, more stable pump operation, longer life of the bearing and mechanical seal, and reduce maintenance and repair costs;

■ The mechanical seal of shaft seal can be cartridge type; Double face mechanical seal can be configured; sb

■ The bearing body is designed with heavy load and is equipped with efficient radiating fins to ensure long-term reliable operation of the bearing. It can be equipped with maintenance free closed bearings or grease lubricated open bearings;

■ The coupling can be equipped with diaphragm coupling, pin coupling, etc;

■ Modular design of parts, high degree of generalization, and reduction of spare parts inventory;

■ The configuration of various special alloy materials to meet the transportation of various special media;

■ Flanges can be manufactured according to GB, ANSI, DIN, JIS and other standards;

texture of material

Cast steel, bronze, 304SS, 316SS, 316LSS, duplex stainless steel and super duplex steel.

SEH booster pump

Conform to ISO5199, ISO2858, GB/T 5656 and GB/T 5657 standards.

application

It shall be applied to RO reverse osmosis, chemical process flow, condensate circulation, demineralized water and seawater desalination pressurization and energy recovery.

Basic parameters 50Hz operation data

■ Diameter DNl32-400

■ Maximum flow 2200m3/h

■ Maximum lift 250m

■ Temperature max.+140 ℃

■ Maximum operating pressure: 80bar

Structural characteristics

■ The pump body adopts double volute design. The rotor back pumping design is easy to maintain without affecting the pipeline;

■ The pump casing adopts the central support, and the installation form is APl610 OH2; Avoid increasing the different shaft degrees between the pump and the driver under high pressure operation, so as to prolong the service life of the pump equipment;

■ Excellent hydraulic model of impeller combined with CFD technology to ensure efficient and energy-saving operation; If necessary, the inducer can be increased to improve the necessary NPSH;

■ The main shaft is heavily loaded, and the deviation of the shaft is minimum under the maximum heavy load, so as to ensure the good operation of the components on the shaft, more stable pump operation, longer life of the bearing and mechanical seal, and reduce maintenance and repair costs;

■ Cartridge mechanical seal with high pressure bearing shaft seal;

■ The bearing body is designed with heavy load and is equipped with efficient heat dissipation fins to ensure long-term reliable operation of the bearing. High load cylindrical and thrust bearings are used with thin oil lubrication;

■ The coupling is equipped with diaphragm coupling;

■ Modular design of parts, high degree of generalization, and reduction of spare parts inventory;

■ Flanges can be manufactured according to GB, ANSI, DIN, JIS and other standards.

texture of material

Cast steel, bronze, 304SS, 316SS, 316LSS, duplex stainless steel and super duplex steel.

Material standard configuration table

|

部件 |

铸铁泵 |

不锈钢泵 |

||||||

|

304SS叶轮配置 |

铜叶轮配置 |

304 SS |

316 SS |

316L SS |

CD4MCu 双相钢 |

2205 双相钢 |

2507 双相钢 |

|

|

叶轮 |

304SS |

铜 |

304SS |

316SS |

316LSS |

CD4MCu |

2205 DSS |

2507DSS |

|

主轴 |

420SS |

420SS |

420SS/304SS |

420SS/316LSS |

316LSS |

2205 DSS |

2205 DSS |

2507DSS |

|

轴承体 |

HT250 |

HT250 |

QT450-10/铸钢 |

QT450-10/铸钢 |

QT450-10/铸钢 |

QT450-10/铸钢 |

QT450-10/铸钢 |

QT450-10/铸钢 |

|

叶轮螺母 |

304SS |

304SS |

304SS |

316SS |

316LSS |

CD4MCu |

2205 DSS |

2507DSS |

|

机封压盖 |

N/A |

N/A |

304SS |

316SS |

316LSS |

CD4MCu |

2205 DSS |

2507DSS |

|

轴承体 |

SKF |

SKF |

SKF |

SKF |

SKF |

SKF |

SKF |

SKF |

|

机械密封 |

SiC-C |

SiC-C |

SiC-SiC/304/F |

SiC-SiC/316L/F |

SiC-SiC/316L/F |

SiC-SiC/2205/F |

SiC-SiC/2205/F |

SiC-SiC/2507/F |

|

联轴器法兰 |

HT250 |

HT250 |

HT250 |

HT250 |

HT250 |

HT250 |

HT250 |

HT250 |

|

传动柱销 |

橡胶包覆钢芯 |

橡胶包覆钢芯 |

橡胶包覆钢芯 |

橡胶包覆钢芯 |

橡胶包覆钢芯 |

橡胶包覆钢芯 |

橡胶包覆钢芯 |

橡胶包覆钢芯 |

|

公用底座 |

钢结构 |

钢结构 |

钢结构 |

钢结构 |

钢结构 |

钢结构 |

钢结构 |

钢结构 |

RELATED PRODUCTS

Online Message